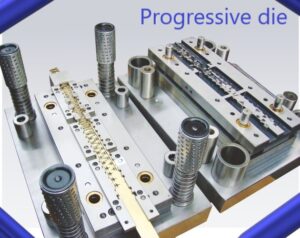

Basically, the decision for making progressive die used to be taken in two cases:

- Parts required in huge volume

- Parts have multiple operation

Keeping these two factors in mind we use to proceed for a progressive die so that we can deliver the required quantity within the committed time period while maintaining the part quality tool life.

Factors to keep in mind while design progressive dies

Orientation of parts:

We need to adjust the orientation by rotating the parts so that an effective and economical strip layout can be made. At the same time grain direction also plays an important role. Bending should be perpendicular to the grain direction.

Carrying the parts

The part should be properly carried in the strip while feeding, it results in good quality of final part produced as all the operations will be done at the right place.

Piloting

Piloting is one of the important factors in progressive tooling, as this ensures that the part is feeding at a constant pitch. Here the tolerance in the pilot hole should be sufficient enough else little elongation in the strip may cause the part rejection.

Piloting can be done on the part if there is any hole that exists in cash there is no hole in parts then we can use piloting in the scrap portion.

Number of stages

The next thing is to define the number of stages where the successive progressive takes place. So here we make a strip layout and number of stations to be defined

A number of stations determine the strength and weakness of the part produced. Idle stations should be avoided.

Conclusion

A good progressive tool should have a good feeding system, less maintenance and long tool life and should ability to produce quality parts in order to meet customer’s requirements.

It should have provision to open punch while Tool is on the press itself as some punches like piercing punches use to have very frequent broken. So quick replacement can help here.