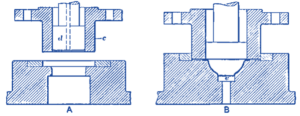

Double-action dies are those type of die in which blanking and drawing punches have independent movements which are derived from the two slides of

a double-action press; hence, the name of the die, in this case,

indicates the type of press in which it is used. A double-action

die of the “push-through” type is illustrated at “A” in below image.

The combined blanking punch and blank-holder “c” is operated

by the outer slide of the double-action press and moves slightly

in advance of the drawing punch “d”, which is actuated by the

inner slide. The outer slide is so arranged that, after making its

stroke, it stops during about one-quarter of a revolution of the crankshaft.

The blank, after having been sheared from the sheet

by the outer edge of punch “d”, is held between the end of punch

“C” and the seat in the die, during the dwell of the outer slide.

While the blank is thus held under a pressure which can be

regulated to suit the special requirements of each case, the

drawing punch “d” continues its downward movement, thus

drawing the metal from between “c” and the die, into the form of

a cylindrical cup. The drawing punch is so timed or adjusted

that it will not reach the blank until the latter is subjected to

sufficient pressure by the blank-holder for the drawing operation.

While this type of die requires a double-action press, it is

very much simpler in construction than the combination die

illustrated in previous figure, which, as previously mentioned, is used in

a press of the single-action type. The design of die shown at

A, in below figure is suitable for cylindrical articles which can be pushed

through the die; hence, it is sometimes called a “push-through”

cutting and drawing die, to distinguish it from the solid bottom

type shown at B, which may be used for producing a cup of the

shape illustrated. As will be seen, both the drawing punch and

die conform to the shape of the part to be drawn. This type

of die is equipped with knockout or “push-out plate” e at the

bottom of the die, which rises on the upstroke of the press and

lifts the drawn part from its seat in the die. This push-out

plate, which is also called a “knockout,” may be either spring actuated or positively operated from beneath (as in the case of

the die illustrated) by connection with the press.

Complete Press Tool design course , Whatsapp for more detail or Call 9914109883