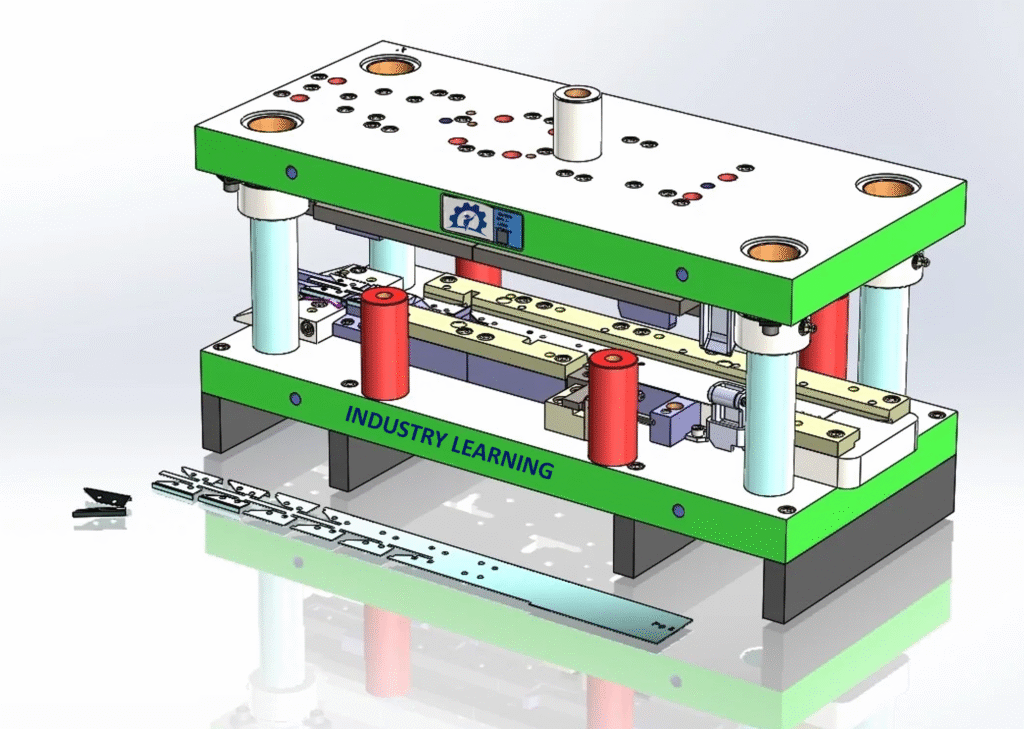

Course on Press Tool Design in NX (Unigraphics)

Topics for this course

WhatsApp 9914109883 for Live demo / Corporate course (Offline/online)

Live session duration: 36 Hrs.

Recorded session duration: 56 Hrs

Introduction to Press tools

- Sheet Metal Operations

- Theory of Shearing

- Elements in a Press tool

- Force Calculation

- Bend allowance calculation

- Strip layout

- Clearance calculation

- Spring Back calculation

- Deep draw

Press Tool Design in NX CAD

- Blanking Tool Design

- Compound Tool Design

- Bending Tool Design

- Draw / forming Tool Design

- Deep Draw Tool Design

- Curling Tool Design

- Progressive tool design

Progressive tool construction and Design in NX (UG)

- Direct unfolding

- Assign material

- Blank nesting/ strip layout

- One-step Unforming to create free form blanks

- Assign stations

- Simulate process

- Manual simulation process for free form part

At the end of the course, the participant will be able to,

- Design different types of Stage Tools

- Design different types of compound Tool

- Design different types of strip layouts – various ways.

- Design of multistage progressive tool – Indirect piloting

- Design of multistage progressive tool – Direct piloting

₹28000

Material Includes

- 36 Hours (36 sessions) of Live training

- 5 assignments on stage tool design

- 5 assignments on Compound Tool design

- 4 assignments on Progressive Tool design

- Support will be provided till you complete its design by yourself

- Soft materials

- NX (UG) Support

- 9:00 Am to 9:00 pm WhatsApp and Call support ( No. 9914109883)

₹28000

-

Duration36 hours

Hi, Welcome back!

Share Course

Page Link

Share on social media

Course Curriculum

Sheet metal design command in NX (Unigraphics)

In this section You will learn the basics of Sheet metal design command in NX :

Sketch - It is the basics of any design.

• Extrude - It creates a feature by extruding a section along a vector.

• Sheet Metal from solid - It builds a sheet metal model that takes its shapes from a collection of planar faces. This command is used to convert the solid body into a sheet metal body. After selecting the command and the solid body, we can also remove the edge sharpness by removing the material at these places.

• Tab - Tab is a command used to create a base for any sheet metal part that can be extruded from a sketch. The sketching plane can be selected as per the designer’s choice.

• Flange - It is used to create an extended part (bend) of a sheet metaL It is created at the edge of one side of the modeL This command will allow us to select the edge of the base to create a projecting flat extruded surface. The angle, width, length, and type of flange can be determined as per the requirements

• Jog - It modifies the model by liking material on one side of a sketch fine, adding a flange between the two sides. Jog is created at another end of the model opposite to the flange. Jog is a command to lift off one whole side of the part By selecting a line and the plane, the material can be pushed down or Lifted off depending on the situation.

• Unbend - This feature is used to unbend the adjacent bends and flatten them. Here it is used to create more features. This command is used to unbend the sheet metal parts to create geometries and work on complicated designs. In this command, we have to select a stationary face and then select the corners of flanges to unbend.

• Rebend - It is used to rebend the corners that were bent before along with any features added aher the unbend feature.

• Bead - It lifts material along the contour of a sketch that simulates a stamping tool, it is used for giving strength to the sheet meta. Here two beads are created on the unbent surface. The selected sketch is lifted off from the base to provide strength to the material. Similar to dimple, the material can be removed in both directions.

• Hole - It adds a hole to one or more solid bodies in a part or an assembly with options for counterbored, countersunk and threaded. Here six simple holes are created on the unbent surface with a diameter of 1O mm. It can be used to make customized or standardized holes along with a defined point or path. The dept of the hole can be controlled.

• Flat pattern - It creates a flat pattern feature from the formed sheet metal part The user chooses this command to create a fiat view of the sheet metal after unbending all the sides and faces. This view can be used in drawing the flat pattern along with the bend radius and other dimensions.

-

Sheet metal design command in NX

46:58

Press Tool concepts

-

Introduction to Press Tool

01:24

Elements of Press Tools

-

About all parts of Press Tools & Its function

09:24

Types of Press Tools

-

Stage Tooling

15:52 -

Compound Tool

58:00 -

Combination Tool

56:00 -

Progressive Tool

58:00

Types of Press tool operations

-

Cutting operation

05:02 -

None Cutting operation

40:00

Tool & Die Material

-

Tool life Vs. Cost

58:00 -

Material Hardness

39:00

Cutting Tools

-

Shearing Mechanism

46:00 -

Shearing Force

04:38 -

Stripping Force

01:32 -

Cutting clearance

01:58:00 -

Scrap Strip Layout

05:07 -

Material Economy

53:00 -

Cost analysis and Cost saving

49:00 -

Other Concept & Calculation

49:00 -

Design in NX (Unigraphics) Blanking Tool-01

15:52 -

Design in NX (Unigraphics) Blanking Tool-02

01:03:11

Bending Tools

-

Mechanism of Bending

42:00 -

Bending force in U Type, V type and Wiping die

48:00 -

Blank development

01:56:00 -

Bend Radius

38:00 -

Bend allowance

11:04 -

Blank Length Calculation

56:00 -

Spring back calculation and compensation

38:36 -

Air bending & Bottoming

02:30 -

Other Concept & Calculation

54:00 -

Design in NX (Unigraphics)

46:08

Standard Item Selection

-

Selection of Guide Pillar, Bush, Spring, PU. Bush and others.

49:00

Compound Tool design

-

Concept & Calculation

39:00 -

Design in NX (Unigraphics)

51:44

Forming Tool design

-

Concept & calculations

58:00 -

Design in NX (Unigraphics)

41:13

Draw Tool design

-

Concept & Calculation

57:00 -

Blank Development

01:42:00 -

Design in NX (Unigraphics)

58:00

Progressive Tool design

-

Concept & Calculation

01:42:00 -

Strip Layout 1

52:49 -

Strip layout 2

50:58 -

Strip Layout 3

14:43 -

Strip Layout 4

11:50 -

Strip Layout 5

11:49 -

Strip Layout 6

11:33 -

Raw material Utilization & Cost analysis

58:00 -

Complete Progressive Tool Design in NX (Unigraphics)

01:08:53

CAD Excercise

-

Progressive Tool Project 01

04:42:00 -

Progressive Tool Project 02

03:42:00 -

Progressieve Tool Project 03

05:36:00 -

Progressiev Tool Project 04

03:48:00 -

Progressiev Tool Project 05

04:42:00