History of injection Moulding

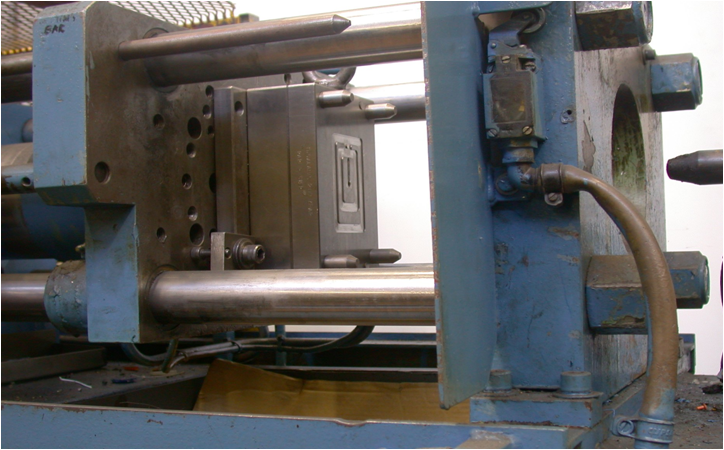

History A natural tropical resin known as Shellac had been in use in the western ethastetarn countries since the middle ages but it was around 18 method was developed for mass production of articles out of it. The first injection…