This class of dies is specifically designed to bend sheet metal or wire components into various irregular shapes. The desired form is achieved by pressing the stock into die cavities or depressions that match the intended shape.

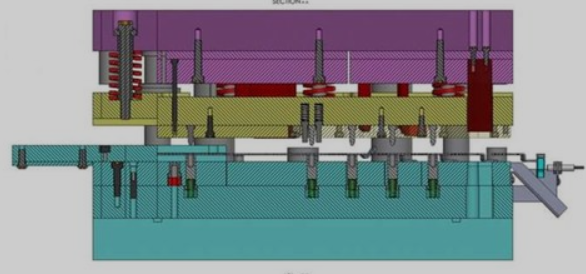

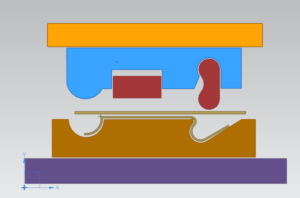

The movement of auxiliary attachments, such as slides, occurs as the punch descends, facilitating the bending process. A basic bending die consists of an upper punch designed to match a depression in the die face. This type of die is often used to bend flat sheet-metal plates into irregular shapes. When working with elastic or springy materials, the die must be designed to accommodate the material’s tendency to return to its original shape. To compensate for this, the part is bent slightly beyond the required angle, ensuring accuracy after the pressure is released. Determining the optimal allowance typically requires experimentation. An important bending die design is shown in Fig.

As illustrated, a swinging arm is pivoted at one end of the punch and carries a steel roller . As the punch descends, the roller guides the stock downward into the die at point . Once its downward motion is restricted by the die, arm pivots to the left and continues moving until the roller fully shapes the work within the die, as seen in the lower finished part. The left-hand section of the workpiece is formed between the die and the punch extension . Before the punch completes its downward stroke, the gripper engages the workpiece, securing it in place using the tension of two springs. This ensures stability and prevents any movement of the blank during the final bending phase.

Join Complete Press tool design course for more detail .

Call 9914109883 .