As the name suggests, operates with three independent movements. This type of die is designed for manufacturing processes that require three sequential operations, including cutting or blanking, drawing, and stamping or embossing. It is often preferred over a solid-bottom double-action die, because it delivers the finished part below the drawing die rather than pushing it upward. This feature allows for continuous feeding without requiring the operator to pause and wait for each piece to be ejected before blanking the next one.

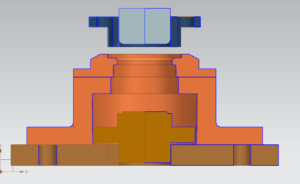

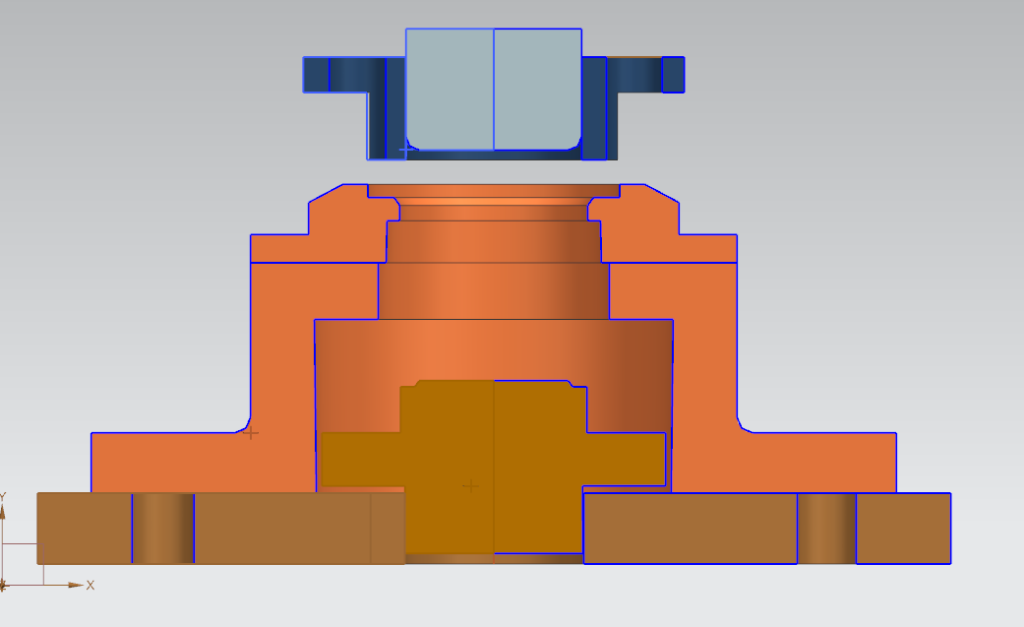

A triple-action die, as depicted in given figure, consists of several key components working in sequence. The cutting and drawing die is securely positioned on a raised bolster . The blank-holder and cutting punch first cuts the blank while simultaneously holding it in place. Next, the drawing and embossing punch descends, drawing the cup downward. As this process continues, the lower surface of the drawn cup meets the embossing die , which is mounted on plunger . During the plunger’s upward stroke, it imparts the desired impression onto the workpiece—whether it be decorative patterns, lettering, or other embossing effects. Finally, as the punch moves upward, the process completes, leaving a precisely formed and detailed product.

Refer image for details .

Whatsaap 9914109883 for more details and complete course on Press Tool design.

or Visist https://industrylearning.co.in/courses/press-tool-design-nx/ .